Are your pencil leads constantly snapping? Broken leads waste materials and slow down production. Find out how we tackle this problem.

While a truly "unbreakable" pencil lead is very difficult, we use several methods to make them much more break-resistant. This involves carefully adjusting the lead formula, improving manufacturing processes, and using high-quality wood casing.

As Andrea from Leadur, I have seen many clients struggle with lead breakage over my 10+ years. Let me share what I know about how we achieve better quality.

Is there an unbreakable pencil?

Tired of leads breaking when you sharpen? Constant breaks frustrate users and cause waste. Learn how to improve lead strength.

No pencil is truly unbreakable. However, by controlling the lead formula and manufacturing steps, we make pencil leads highly resistant to breaking during normal use and sharpening. It is about making them much stronger, not completely invincible.

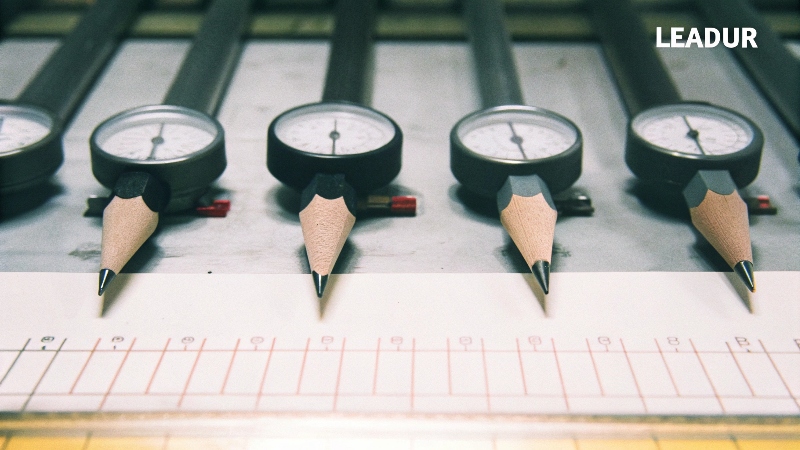

Let's talk about what "unbreakable" really means for a pencil lead. It means it does not break easily. Reaching zero breaks is almost impossible. We aim for very few breaks. We look at how the lead performs when used and when sharpened. We adjust the lead mix. We use special clays and binders. These materials hold the graphite together. More binder can make lead stronger. Less graphite makes it harder. But less graphite also makes it lighter in color. We must find the right balance for the needed grade, like HB or 2B. We also think about the wood case. Good wood supports the lead. If the wood cracks when sharpened, the lead can break too. Using high-quality wood1 like Basswood or Incense Cedar helps. These woods sharpen smoothly. This protects the lead inside. We test lead strength2 often during production. We check bending strength and breaking points. This helps us catch issues early. We want lead that stays whole when it needs to. My team tests samples from every batch. We bend them and press on them. This tells us how strong the lead is before it goes into a pencil.

-

Key Factors for Lead Strength:

- Lead Formula: Balance of graphite, clay, binders.

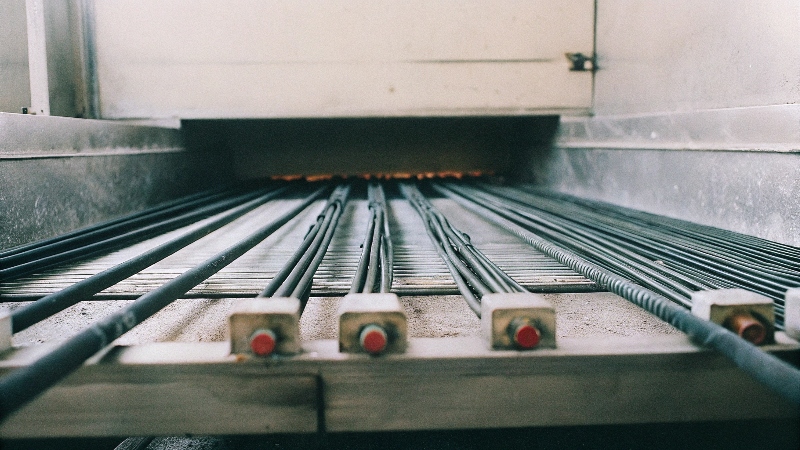

- Manufacturing Process: Mixing, extruding, firing, bonding to wood.

- Wood Quality: Type of wood, how it's bonded to the lead.

- Testing: Regular checks on strength and breakage rate.

-

Comparison of Lead Strength Factors:

| Factor | Impact on Strength | Notes |

|---|---|---|

| Clay/Binder % | High | More = Stronger (can affect darkness) |

| Graphite % | High | Less = Harder (can affect darkness) |

| Firing Temp | Medium | Affects material fusion |

| Wood Type | High | Good wood supports lead |

| Lead-to-Wood Bond | High | Poor bond allows lead to shift/break |

What is the strongest pencil lead?

Do your customers complain about lead snapping? Weak lead means frustrated users and returned products. Discover what makes lead strong.

The strongest pencil leads are typically the hardest ones, like H grades. H leads contain more clay binder and less graphite than B leads. This makes them more rigid and less prone to breaking under pressure, though they write lighter.

When people ask about the "strongest" lead, they usually mean the one that resists breaking the most. Generally, this is about hardness. Harder leads use a higher ratio of clay binders to graphite. These binders act like glue. They hold the graphite particles tightly together. This makes the lead stiff. So, leads like 6H, 4H, 2H, and H are typically stronger than HB, B, 2B, and darker grades. However, strength is not only about hardness. It also depends on the quality of the raw materials we use. We source high-grade graphite and clay3 from trusted places. The size of the particles matters too. Smaller, consistent particles make a stronger lead structure. The way we mix, extrude, and fire the lead also affects its strength. A lead fired at the correct temperature has a stronger internal bond. My team works hard to get this process right every time. We make sure the lead has good bending strength. This means it can flex a little before it snaps. This is important when someone pushes hard on the paper. It's also important during sharpening. We use special machines to test lead strength constantly. This helps us check quality during production. We want clients to get lead that performs well in their pencils.

-

Lead Hardness vs. Strength:

- Hardness (H grades): More clay, less graphite. Generally stronger, writes lighter.

- Softness (B grades): Less clay, more graphite. Generally weaker, writes darker.

-

Other Strength Factors:

- Raw Material Quality: Purity and particle size of graphite/clay.

- Processing: Mixing, extrusion, firing temperature.

- Testing: Quality control checks for bending strength.

-

Typical Lead Grades and Strength (General):

| Grade | Hardness | Strength (Relative) | Writing Darkness |

|---|---|---|---|

| 6H | Very Hard | Very High | Very Light |

| H | Hard | High | Light |

| HB | Medium | Medium | Medium |

| B | Soft | Medium Low | Dark |

| 2B | Softer | Low | Darker |

| 6B | Very Soft | Very Low | Very Dark |

Does 2B lead break easily?

Is your 2B lead giving you headaches with breakage? Darker leads are popular but can be fragile. Let's fix this problem.

2B lead is softer and contains more graphite than harder grades like HB or H. This means it is generally more prone to breaking compared to harder leads. However, good quality 2B lead manufactured correctly can still be quite durable.

Yes, 2B lead4 is known to break more easily than harder leads. This is because of its composition. 2B lead has more graphite and less clay binder compared to an HB or H lead. Graphite is soft. The clay binder is what makes the lead hard and strong. With less binder, the structure is not as rigid. It is more flexible and darker, but also more fragile. Think of it like comparing hard plastic to soft rubber. The hard plastic (H lead) snaps but resists bending more. The soft rubber (2B lead) bends easily but might tear more. However, we make millions of 2B leads every day. We know how to make high-quality 2B lead that minimizes breakage. We use specific types of clay and binders that help improve flexibility without losing too much strength. We control the firing process very carefully. This sets the lead's structure. We also pay close attention to the wood casing for 2B pencils. The wood must support the softer lead well. If the lead-to-wood bond is weak, the 2B lead can shift and break inside the wood. Our quality control5 checks focus on 2B leads specifically. We test their strength and sharpening performance often. We want clients to get the dark, smooth line of a 2B lead without constant frustration from breaks. This is why our B grades are popular even though they are softer.

-

Why 2B Leads Break More:

- Higher Graphite Content: Graphite is naturally soft.

- Lower Binder Content: Less clay to hold particles together rigidly.

- Increased Flexibility: Bends more, can snap under shear force.

-

How We Improve 2B Strength:

- Optimized Formula: Specific binder types and ratios.

- Precise Firing: Curing process for better internal structure.

- Strong Wood Bond: Ensures lead is well-supported by casing.

- Rigorous Testing: Checks performance under stress.

-

Comparison: 2B Lead vs. HB Lead Breakage:

| Feature | 2B Lead | HB Lead |

|---|---|---|

| Graphite Ratio | Higher | Lower |

| Clay/Binder Ratio | Lower | Higher |

| Hardness | Softer | Medium |

| Breakage Tendency | Generally Higher | Generally Lower |

| Writing Darkness | Darker | Medium |

How do you harden pencil lead?

Need lead that stands up to sharpening? Making lead stronger is a science. Learn how we do it right.

We harden pencil lead primarily by adjusting the ratio of clay binder to graphite in the mix. More clay binder makes the lead harder and stronger. We also control the firing temperature precisely, which affects the final hardness and structure.

Hardening pencil lead is a key part of our manufacturing process. It is not just about making it hard, but also strong and consistent. The main way we increase hardness is by changing the formula. We use a mix of graphite powder6, clay, and water. For harder leads, we increase the amount of clay. Clay particles bond together when heated. This creates a strong structure around the graphite particles. The more clay, the tougher the bond. The less graphite, the lighter the mark, but the harder the lead. We also add special binders to the mix. These help improve the lead's bending strength. After mixing, we extrude the lead into thin rods. Then we dry them slowly. The next critical step is firing them in a kiln at very high temperatures. The temperature and time in the kiln are very important. This process hardens the clay and fuses the materials together permanently. Too low a temperature, and the lead is weak. Too high, and it becomes brittle. We have perfected this process over years of work. We use precise temperature controls7 and monitor it closely. The wood casing and how the lead is glued into it also affects perceived hardness and breakage. A well-bonded lead feels more stable inside the wood. It is less likely to twist or break when sharpened. We use high-quality wood and strong adhesive to ensure this bond is secure. Finally, even the sharpener used matters. A good, sharp sharpener cuts the wood cleanly without stressing the lead. A dull or poor sharpener can twist or push on the lead, causing it to snap inside the pencil. We advise clients on best practices for assembly and sharpening to help their end users.

-

Steps to Harden Lead:

- Formulation: Adjust ratio of graphite to clay/binders.

- Mixing & Extrusion: Prepare and form the lead rods.

- Drying: Remove moisture before firing.

- Firing (Kiln): Heat treats the lead, fusing materials.

- Bonding: Secure lead inside high-quality wood casing.

-

Impact of Raw Materials and Process on Hardness:

| Input/Process | Impact | Notes |

|---|---|---|

| Graphite % | Decreases H | Higher % means softer (B grades) |

| Clay/Binder % | Increases H | Higher % means harder (H grades) |

| Firing Temp | Increases H | Must be precise; too high=brittle |

| Wood Quality | Supports Lead | Good wood prevents bending/breakage |

| Lead-Wood Bond | Supports Lead | Prevents internal movement |

Conclusion

Making lead break less is a mix of formula, process, and quality wood. We test constantly to ensure durable leads.

-

Exploring the advantages of high-quality wood can reveal how it enhances pencil durability and performance. ↩

-

Understanding lead strength is crucial for ensuring high-quality pencils that perform well and resist breaking. ↩

-

Graphite and clay are essential for pencil lead quality. Learn how they impact performance and durability by checking out this informative link. ↩

-

Explore the unique properties of 2B lead and understand why it's favored for its smooth writing experience and dark lines. ↩

-

Discover effective quality control measures in pencil production to ensure high performance and customer satisfaction. ↩

-

Exploring the significance of graphite powder can provide insights into material selection and performance in pencil production. ↩

-

Learning about temperature controls can help you grasp the importance of precision in manufacturing for optimal product quality. ↩